Driving Logistics Industry Transformation

Economic recovery is a challenging process. The Chinese economy, after undergoing the baptism of the pandemic, has demonstrated infinite resilience and vitality to accelerate the process, bringing a hint of warmth from the East to the globally sluggish economy.

As an integral part of the global economy, the logistics industry has always been an area attracting significant investment. The development of the logistics industry is closely related to the growth of the global economy, and the efficiency and cost of logistics have a huge impact on global trade.

Smart warehousing, as an important branch of the logistics industry, is rapidly developing and continuously driving the transformation of the logistics and supply chain industry.

The Product of Warehouse Automation: JD Logistics

On February 8, 2023, JD Logistics REIT was listed, becoming the first large-scale platform enterprise green light case in the field of capital markets. This has a positive demonstration effect on supporting the development of the platform economy and private economy in the capital market.

The development of intelligent warehousing

In China, where labor costs are increasing year by year and the demographic dividend is gradually disappearing, intelligent warehousing equipment systems achieve unmanned operations. This not only greatly saves human resources and reduces labor costs but also improves logistics processes, enhances product security, and provides customers with more convenient and efficient services. Therefore, intelligent warehousing plays a very important role in the logistics industry.

With the advancement of technology, intelligent warehousing equipment systems are no longer simple warehouse storage facilities. Instead, they integrate automated vertical warehouses with enterprise procurement systems, production systems, sales systems, distribution systems, etc., forming an intelligent logistics chain. The extension and expansion of intelligent warehousing equipment not only bring new development opportunities to the intelligent warehousing equipment industry but also bring more value to customers, helping them achieve intelligent manufacturing.

Automation technology is widely applied.

The intelligent warehousing equipment system features prominent characteristics such as systematized management, operational informatization, automated storage and transportation, data intelligence, network collaboration, and intelligent decision-making.

By utilizing automation equipment, networking technology, sensors, and more, intelligent warehousing enables rapid, efficient, and accurate storage and management of goods.

Conveying Equipment for Smart Warehousing

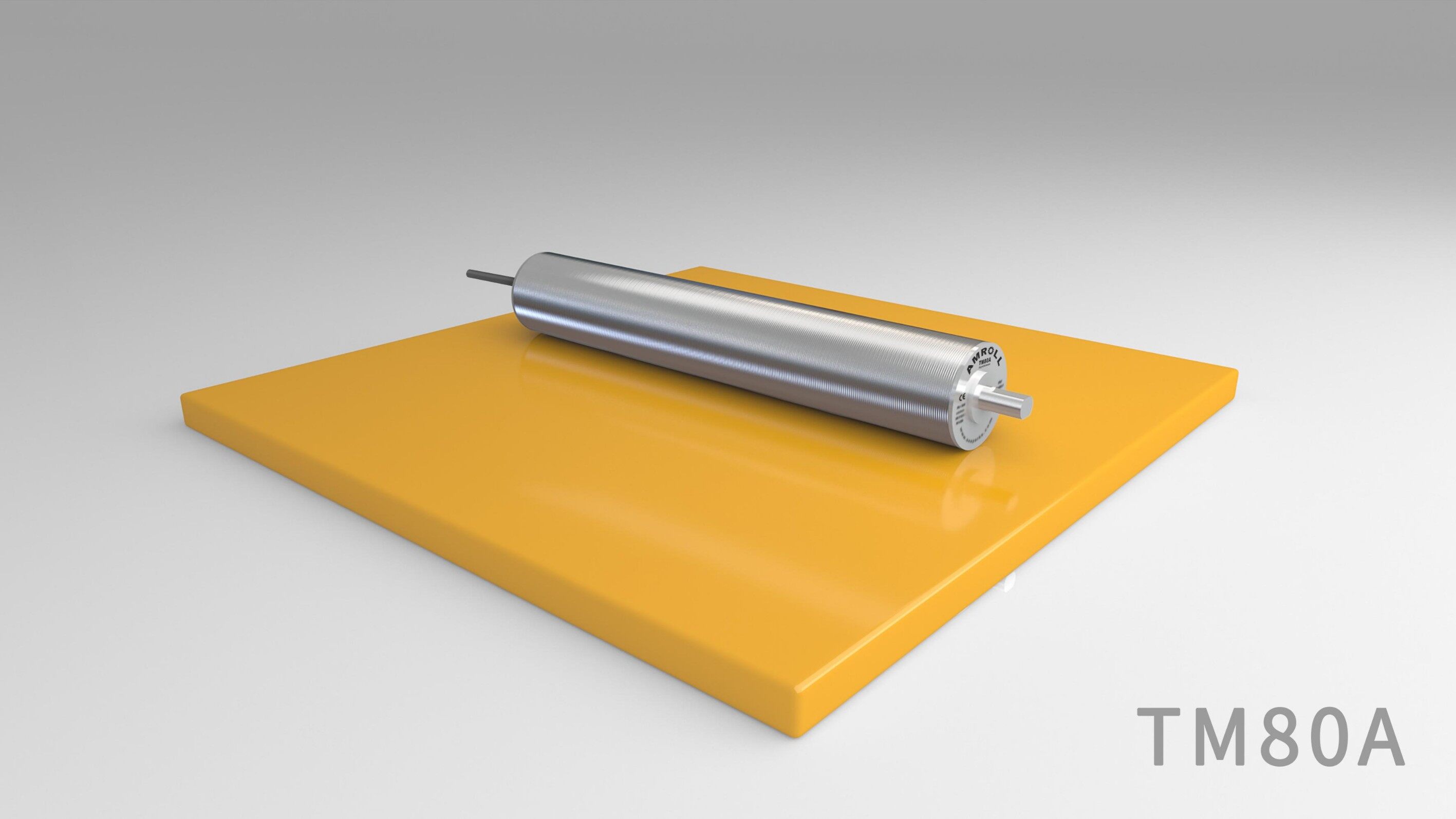

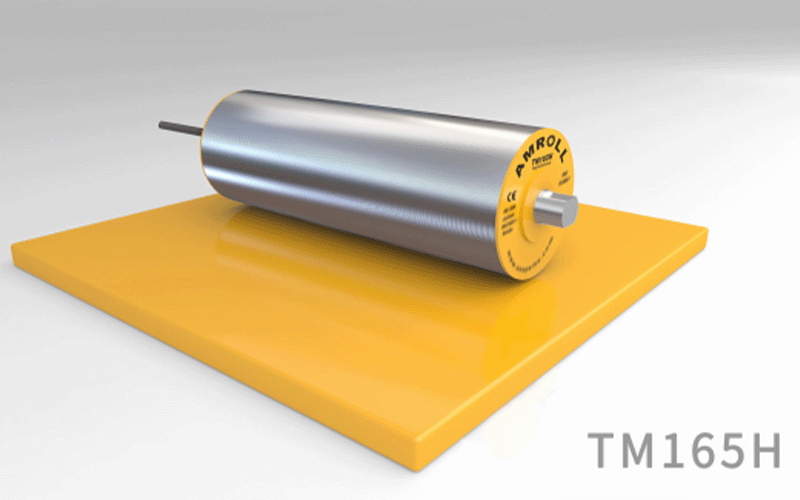

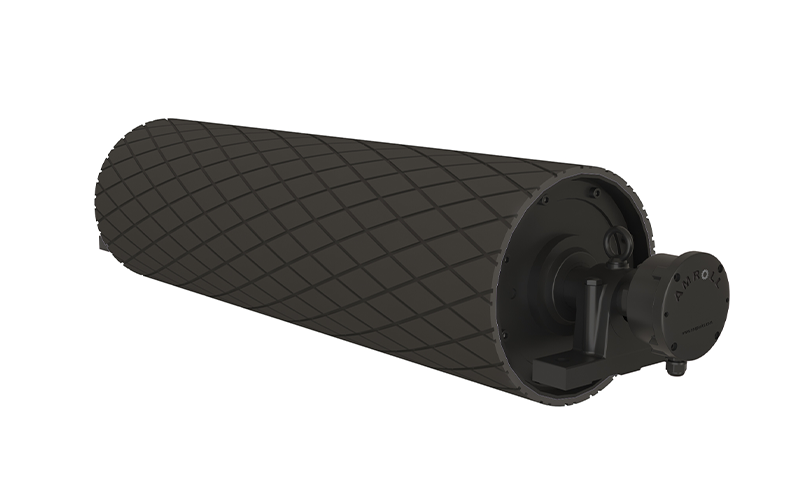

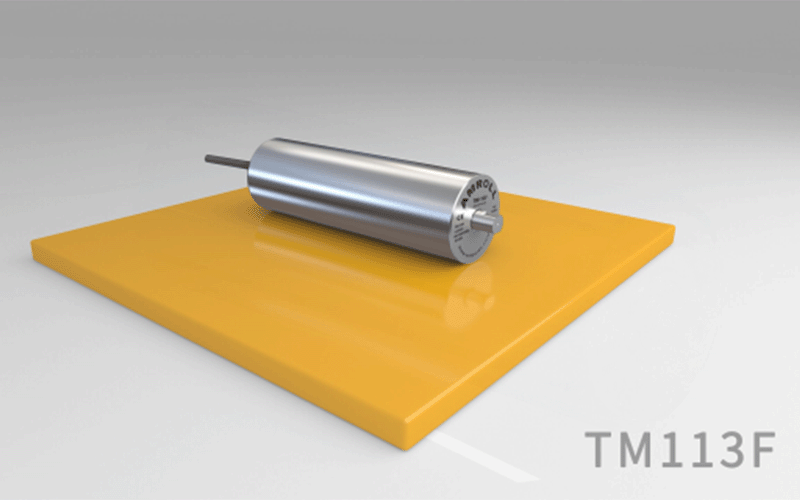

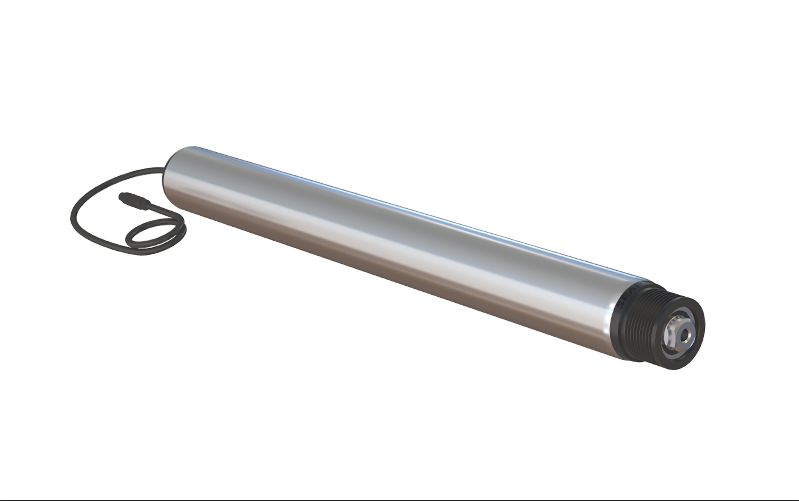

The motorized roller conveyor is a commonly used conveying equipment in smart warehousing systems, holding a crucial position in practical applications. It is a mechanical device that utilizes an internal motor to drive rollers for material transportation. It offers advantages such as high speed and stability.

It can automatically transport materials from one location to another. In smart warehousing systems, it enables automated conveying, significantly enhancing production and logistics efficiency while reducing operational costs, thereby providing great convenience for enterprise logistics management.

The efficient propulsion of motorized roller conveyors.

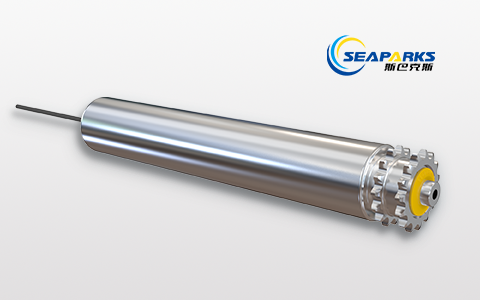

Tianjin Seaparks' pallet series motorized roller conveyors offer the advantages of easy operation and convenient maintenance. They not only meet the logistics needs of intelligent warehousing systems but also fulfill requirements for different environments and working conditions.

Moreover, these motorized roller conveyors can be used in conjunction with other intelligent warehousing equipment to achieve more refined and efficient logistics management.

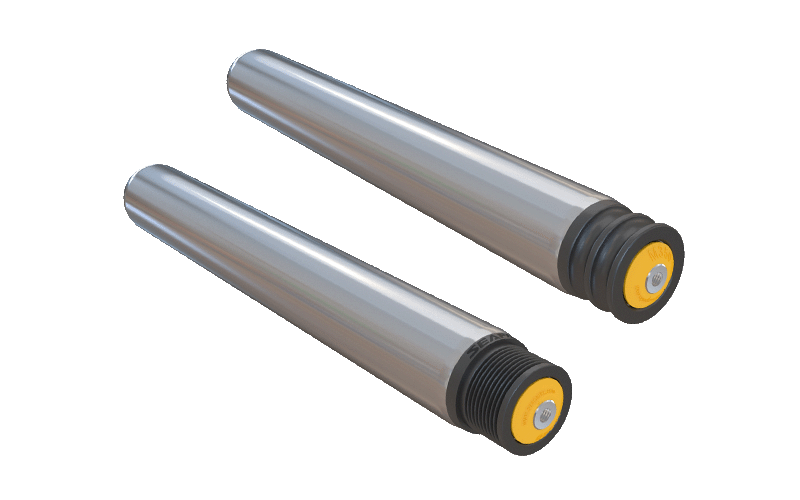

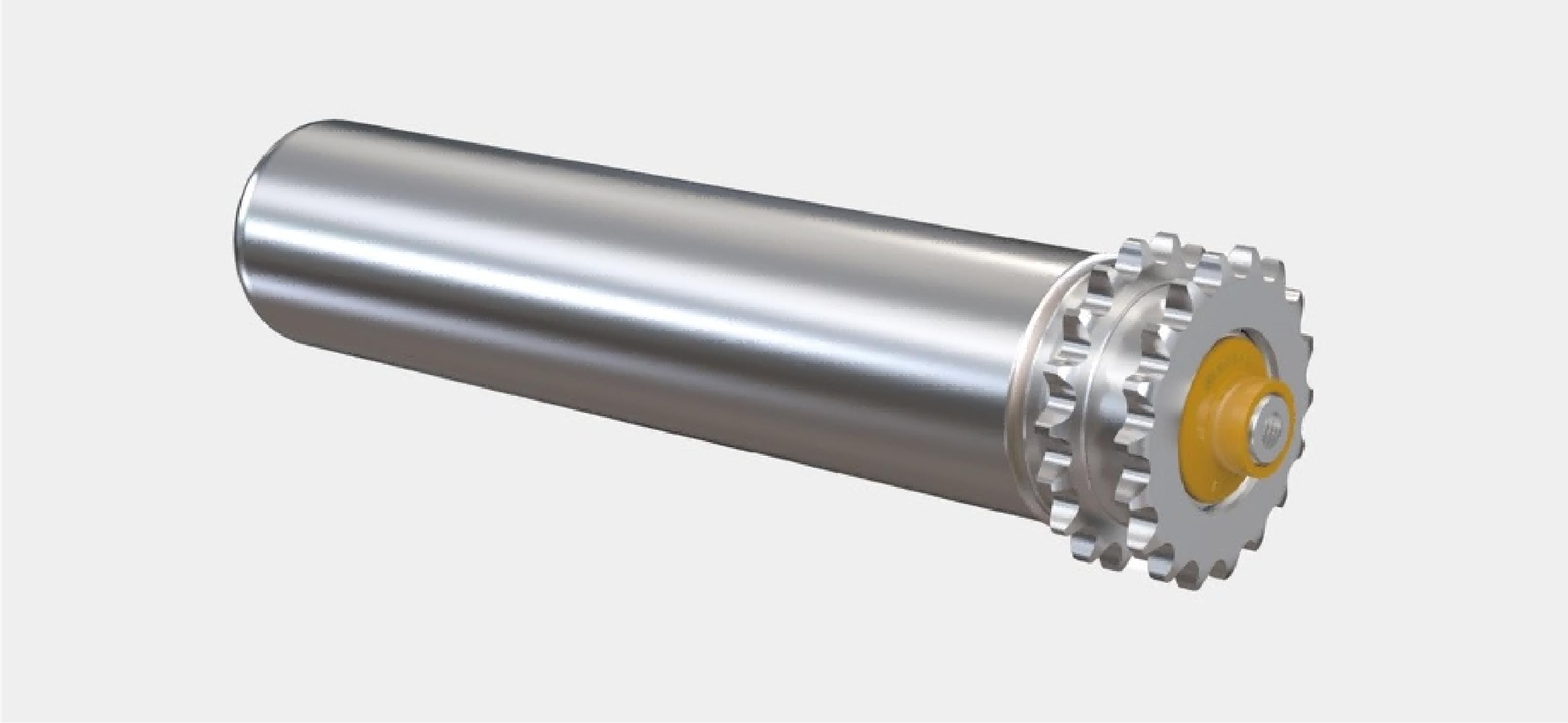

The TP80 and TP89 pallet series are designed for automatic loading and unloading conveyor systems in express logistics. With a maximum load capacity of up to 1.5 tons, they are high-performance and reliable material handling conveyors. The surface of these conveyors is made of galvanized or chrome-plated material, with an IP54 protection rating, suitable for environments ranging from -5°C to +40°C.

Featuring high-alloy steel precision-ground gears, European standard motors, and rigorous assembly requirements, these conveyors offer various drive forms such as single sprockets and double sprockets. Compared to external drive systems, the integrated motor design reduces energy consumption by minimizing losses between multiple transmission components.

Tianjin Seaparks focuses on addressing customer challenges and innovation requirements, providing competitive conveyor drive solutions and services. We are committed to continuous innovation and improvement in the future.