JD Retail undergoes a massive organizational restructuring JD Retail recently announced an unprecedented organizational restructuring, interpreted by the industry as its largest adjustment since 2018. This reorganization upgrades its business units to business groups, continuing JD's long-standing "Big Boss" mechanism.

This mechanism was proposed by JD's founder, Liu Qiangdong, in 2019. The core concept is to treat each small business unit as an independent operating entity, with each entity manager being a true boss, possessing decision-making power. This aims to enhance the responsiveness of business departments to customers and the market, thereby improving operational efficiency.

As the "economic artery" of the national economy, the logistics industry provides indispensable logistics services to various sectors, ensuring the orderly conduct of socio-economic activities. Within the entire socio-economic system, the logistics industry plays a crucial role in service functions and support, serving as a closely interconnected bridge and link.

In today's global context, there is a surge in demand for automation, with industries racing to pursue intelligent transformation. The domestic intelligent logistics industry in China is flourishing. For enterprises dedicated to the production and manufacturing of automated equipment, how to continuously improve their own level through both internal and external technological advancements, and drive the continuous iteration and upgrade of products, has become an urgent issue.

In automated warehousing systems, pallet conveyor lines serve as a crucial component of overall logistics solutions, with their efficiency determining the overall operational efficiency of the logistics system. Pallet conveyor lines are primarily used to achieve automated material handling, temporary storage buffering, and seamless system integration.

As a vital component of logistics and warehousing systems, pallet conveyor lines provide essential support for the entire inbound and outbound system, and their efficient operation has been applied in major logistics distribution centers, providing customers with a satisfactory user experience.

The pallet conveyor line is also equipped with an intelligent management system, which is interconnected with the internal warehousing and logistics management system of the enterprise. This enables remote monitoring and visualized management, enhancing the operational efficiency of the enterprise.

Standardized Design

Standardized operation procedures and modular design are key features of pallet conveyor systems. The modular design allows for different combinations to achieve different effects, making process flows universal, installation pre-assembly modular, construction standardization, and safety design humanized, thereby shortening process cycle times and improving operational efficiency of enterprises.

Customized Services to Meet Customer Needs

The pallet conveyor line is also equipped with an intelligent management system, which, through interconnection with the enterprise's internal warehousing and logistics management system, enables remote monitoring and visualized management, thereby enhancing the operational efficiency of the enterprise.

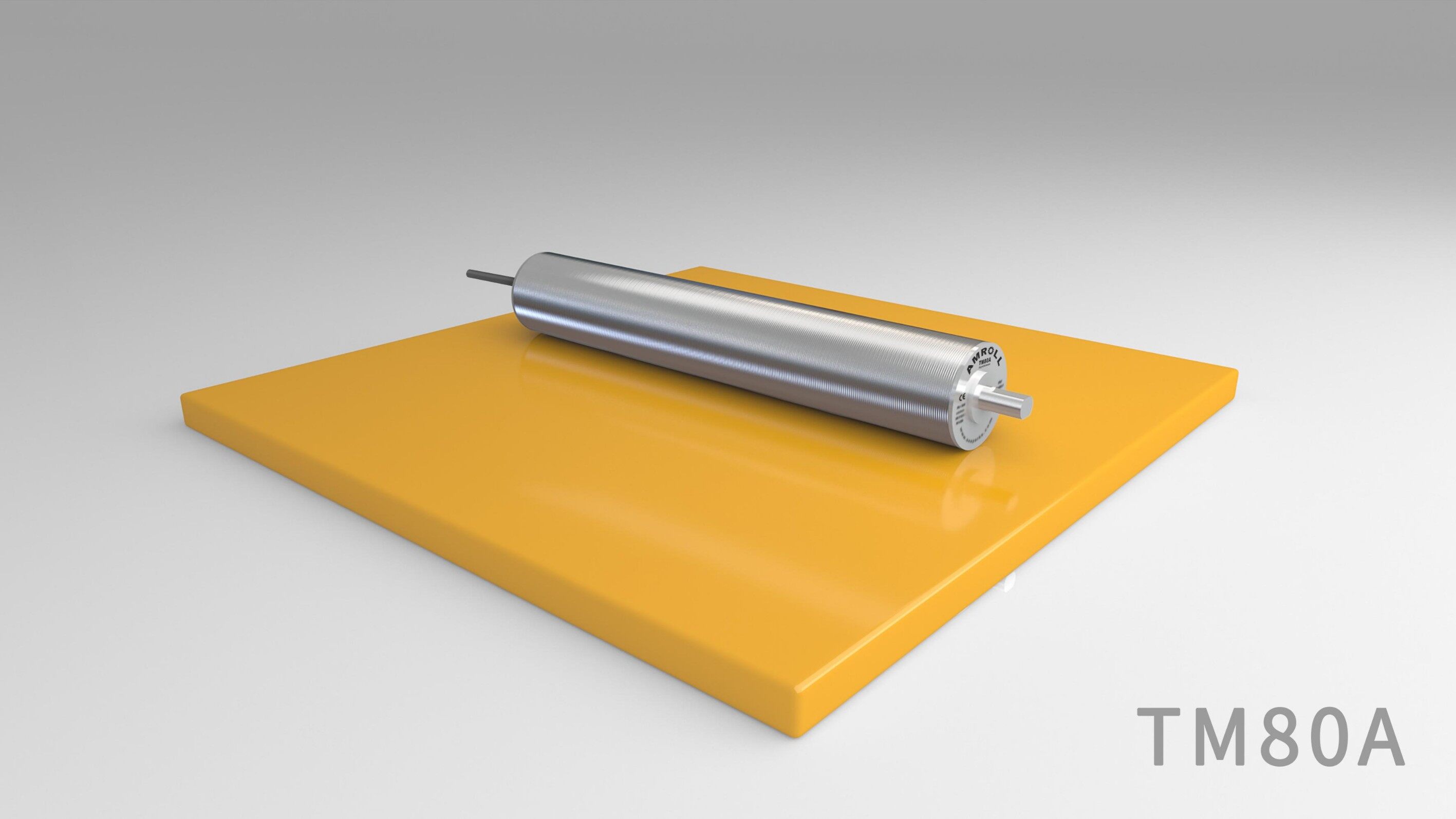

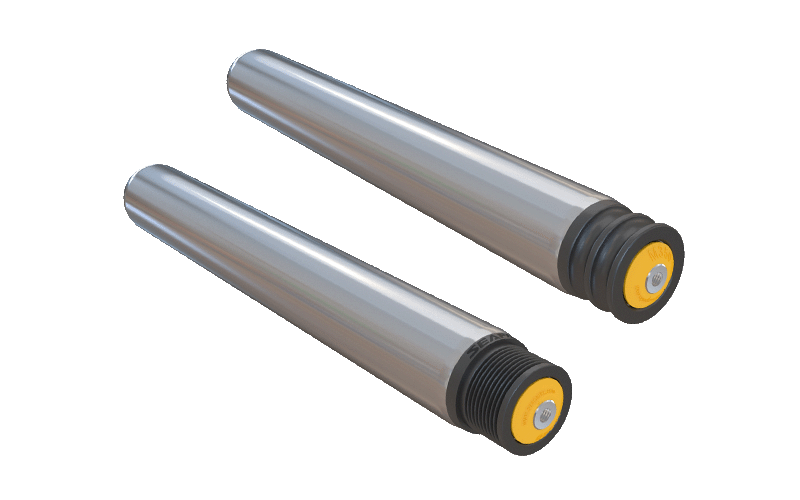

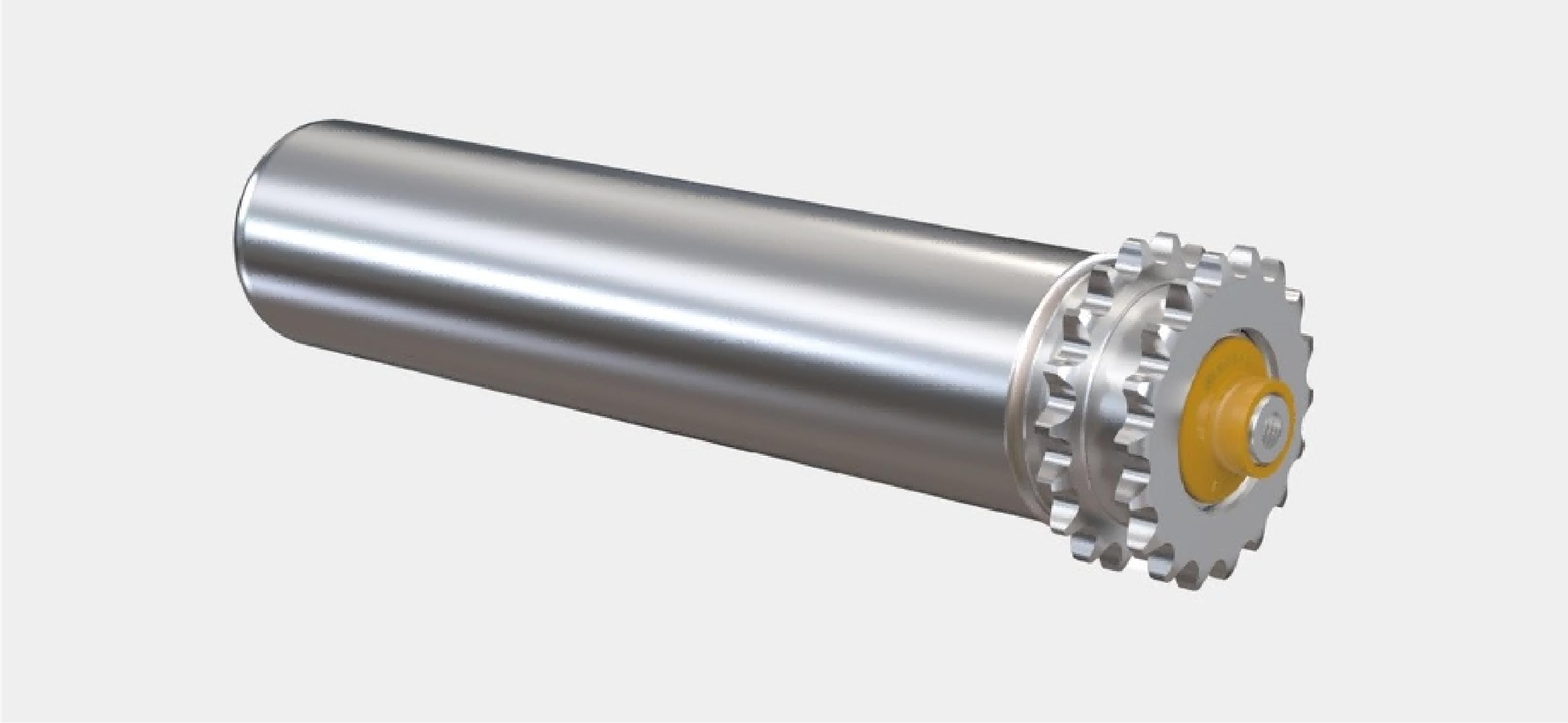

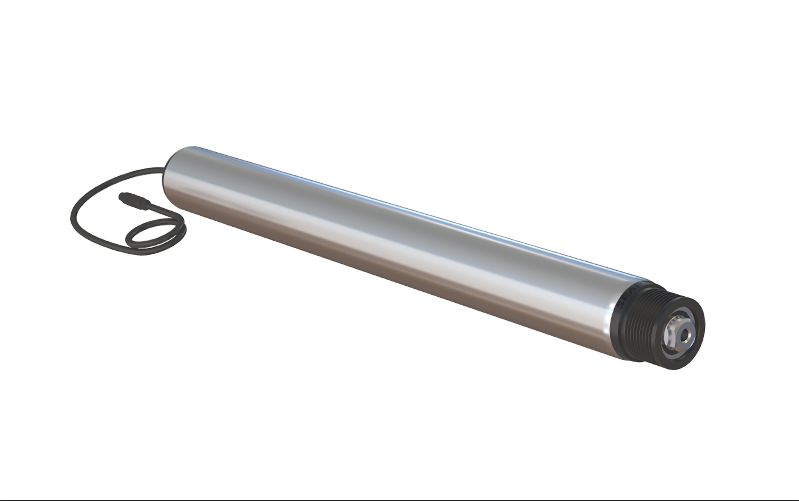

Core Components of the Conveyor Line

The TP80 motorized roller, as a core component of the pallet conveyor line, boasts excellent performance and adaptability:

- 1. Power:

The power of the TP80 motorized roller is 0.07 kW, which provides sufficient power in pallet conveyor systems while also having low energy consumption.

- 2. Rated Voltage/Rated Frequency:

The TP80 motorized roller has a rated voltage of 3*220 or 3*380V and a rated frequency of 50Hz, suitable for common three-phase power supplies and compliant with standard voltage and frequency requirements.

- 3. Duty Cycle:

The TP80 motorized roller has an S3 50% duty cycle, indicating its suitability for periodic loads and normal operation within a 50% duty cycle.

- 4. Gear Stages and Speed Ratio:

The TP80 motorized roller adopts a 2-stage gear transmission with a speed ratio of 62.70, providing appropriate speed and torque output to meet the requirements of pallet conveyor systems.

- 5. Maximum Speed:

The maximum speed of the TP80 motorized roller is 0.20m/s or 0.33m/s, enabling faster pallet conveying speeds and improving production efficiency.

- 6. Protection Grade:

The TP80 motorized roller has an IP54 protection grade, offering good dust and water resistance suitable for various working environments, including places with dust and moisture.

- 7. Temperature Range:

The TP80 motorized roller can operate normally within an environmental temperature range of -5°C to +40°C, adapting to temperature changes within a certain range.

- 8. Drive Head Options:

The drive head of the TP80 motorized roller offers options for sprocket sizes, including 5/8", Z15, Z18, or other sizes, and can also provide timing belt pulleys to meet the requirements of different pallet conveyor systems.

- 9. Cable:

The TP80 motorized roller uses a 6-core cable, including three-phase lines, ground lines, and thermal protection lines, for connecting the motorized roller to ensure reliable and safe electrical connections.

- 10. Maximum Load:

Under normal operating conditio

In the modern logistics field, pallet conveyor systems are widely used. As a key component of logistics warehouse systems, the TP80 motorized roller can operate smoothly in different working environments, providing stable power output and high operational efficiency, thus offering customers a positive user experience.