Since mid-December 2022, there has been an unusual quietness on the streets of northern cities in China, accompanied by some new changes. These changes are expected to propel the Chinese economy back onto a rapid development track in 2023, marking the beginning of global economic recovery led by China.

The personnel shortage brought about by the COVID-19 pandemic, along with the renaming of COVID-19 to COVID infection, has prompted the implementation of the "new ten measures" policy nationwide for some time. From the north to the south, various industries have been impacted to varying degrees in the face of large-scale infections. This has led to rising labor costs and shortages across industries.

The three-year-long pandemic has dealt a severe blow to the real economy, but it has brought development opportunities for online e-commerce platforms. With changes in consumer habits, corresponding logistics services are also being reshaped. After the relaxation of pandemic policies, many restrictions have been significantly reduced. Efficient fulfillment in the logistics process is considered crucial by many industries.

From the perspective of optimizing resource allocation in the logistics industry, the high stability and reliability of logistics facilities and equipment are increasingly valued by manufacturers, leading to a rising demand for logistics equipment.

To improve efficiency and meet the needs of different customer groups, logistics companies need to enhance their level of automation in transportation, warehousing, and distribution, thereby increasing labor and space efficiency, and ultimately improving service quality.

Integrated or unified driving solutions will be a new direction for conveyor equipment in the logistics industry, enhancing sorting efficiency, where automated sorting equipment plays a crucial role.

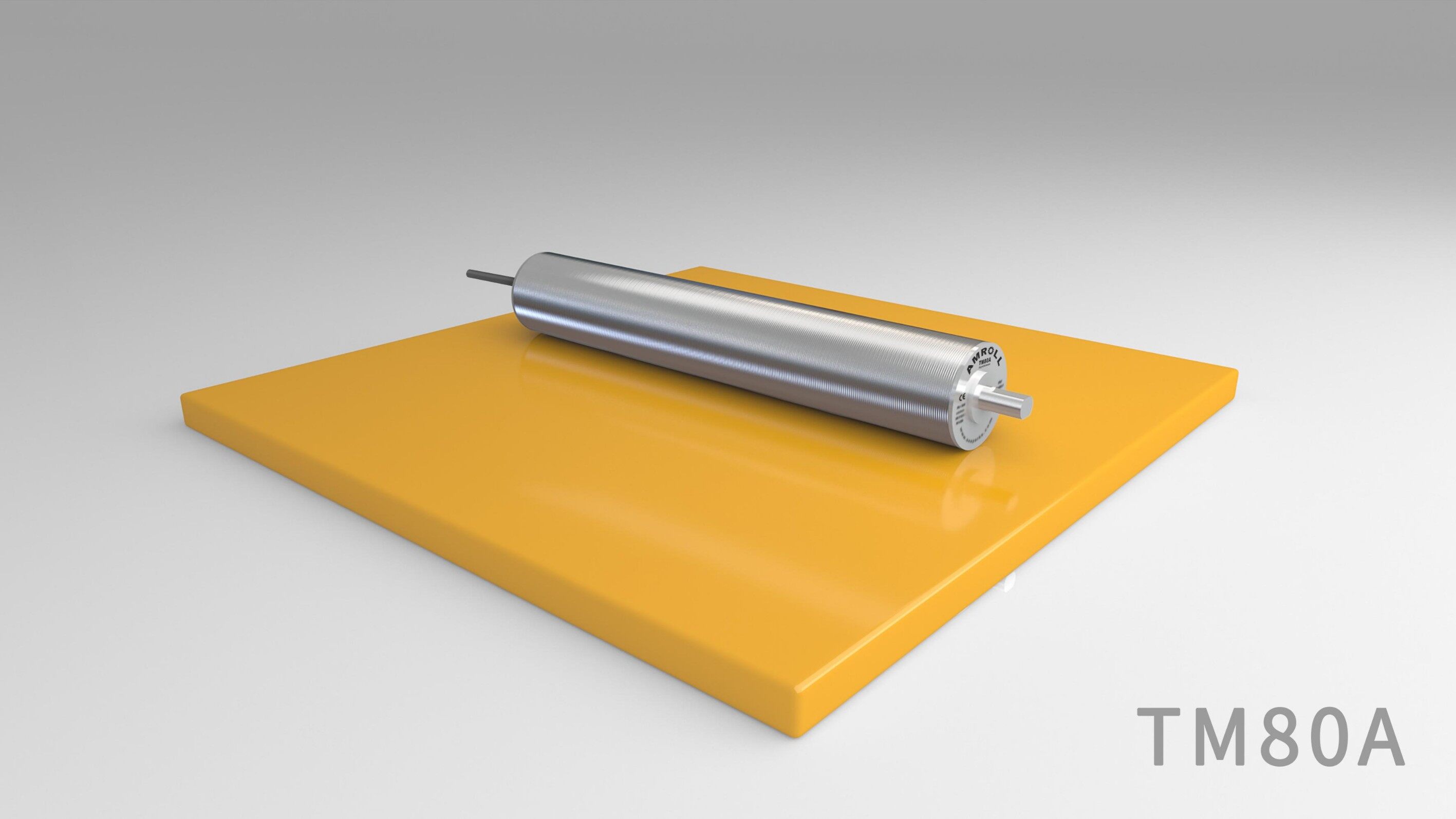

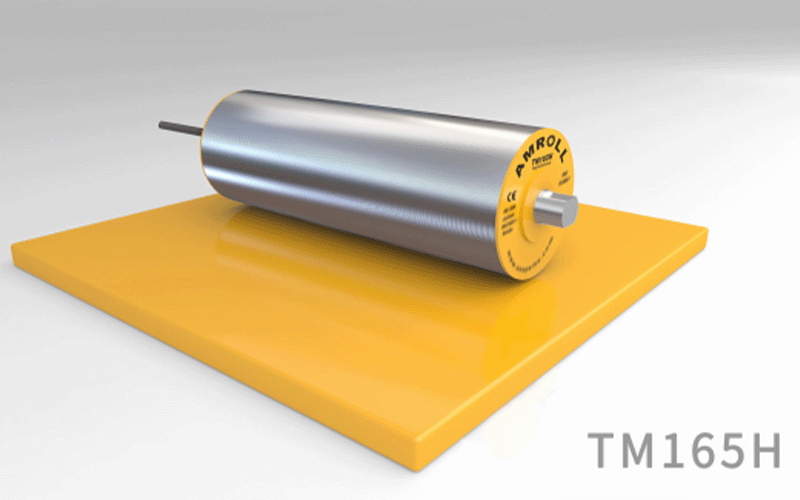

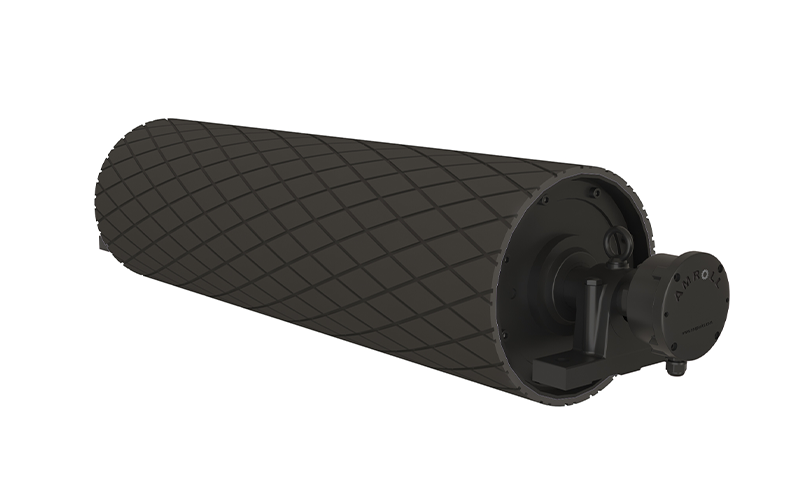

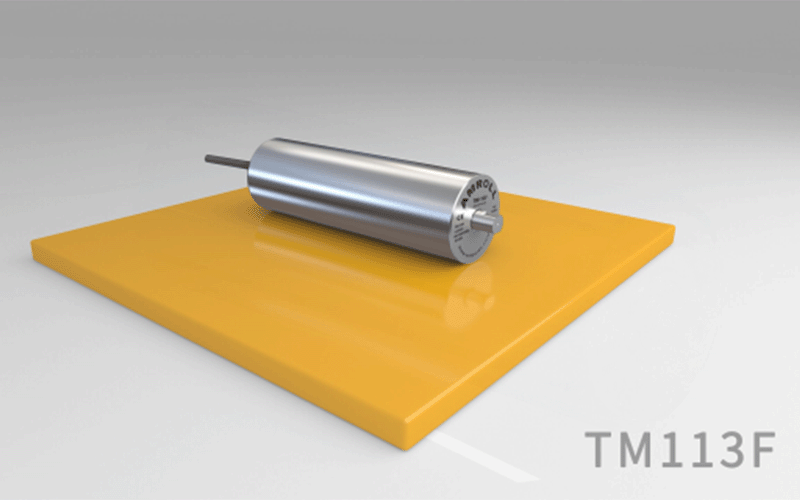

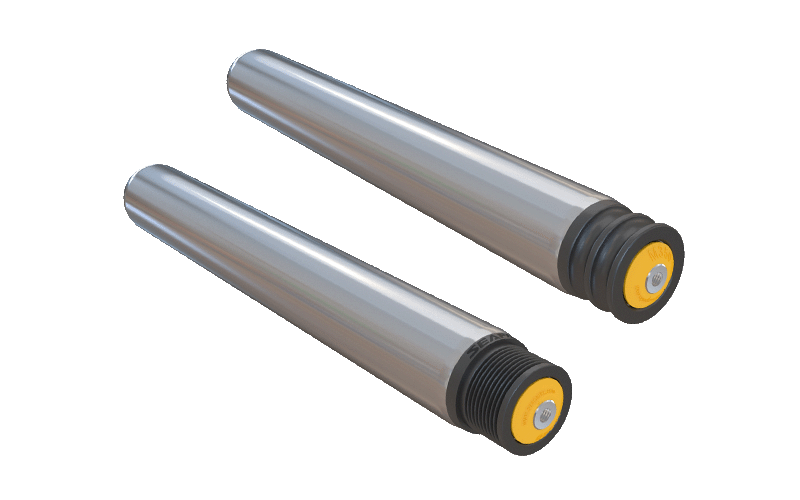

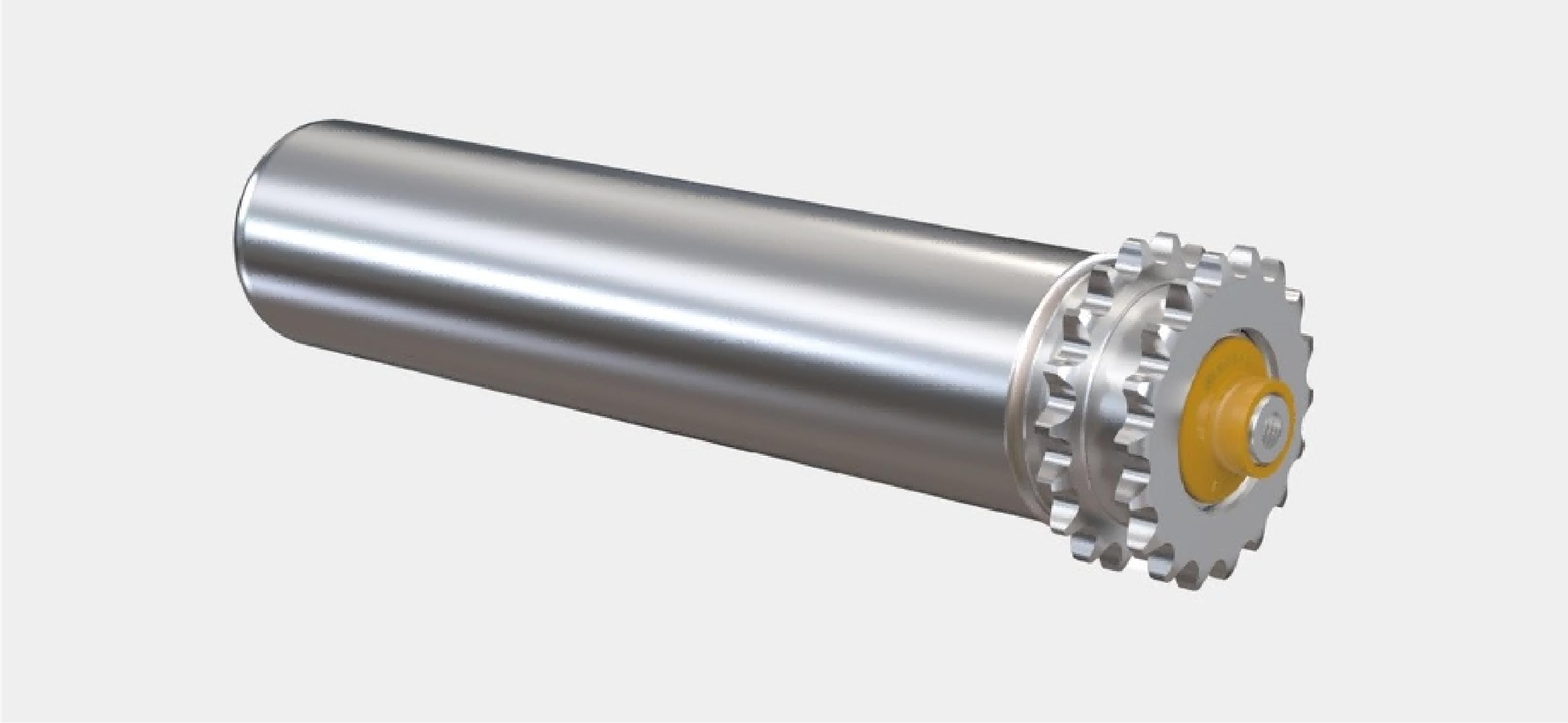

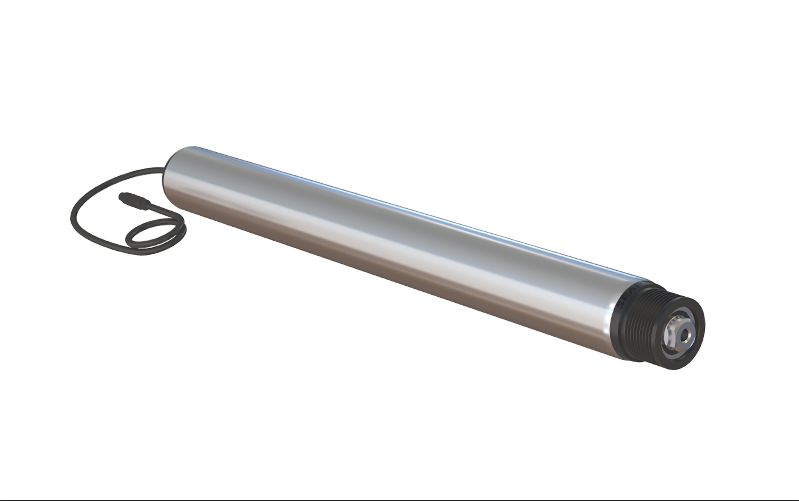

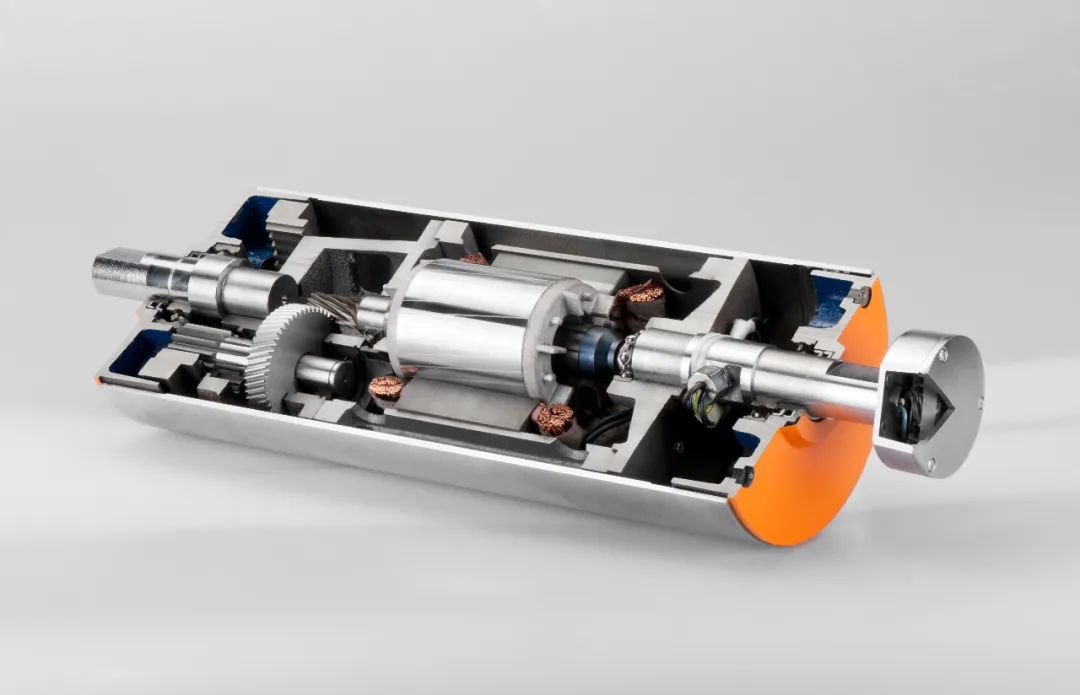

The core of an automated sorting system lies in the selection of conveyor equipment. In situations with limited space, drum motors can replace traditional gear reducers to meet torque requirements.

In terms of material, the design incorporates precision-ground gear transmission structures made of high-alloy steel. The built-in motor can be selected from permanent magnet synchronous motors or asynchronous motors, ensuring high reliability, stability, and energy efficiency.

Compared to traditional gear reducers, drum motors occupy less space, are easier to install, and offer more stable, secure, and efficient operation.

Establishing industry benchmarks.

Tianjin Seaparks M&E Co., Ltd., specializing in the manufacturing of precision logistics equipment, has exported to over 40 countries and regions worldwide, widely used in the logistics and express sorting industries. In the field of core transmission components for conveying equipment, Seaparks' expertise and service are worthy of every customer's trust.