TM216H asynchronous oil immersed drum motor,It is a heavy roller designed for conveying single heavy items or bulk materials. Its power range is 0.37kw to 4.0kw.This kind of drum motor is typically used in:

Motor type:Asychronous, AC, 3 phase

Key words:Belt drive, Oil-filled

Tag:Heavy-duty, Strong torque

AMROLL Drum Motor TM216H-3 *400V/50Hz |

|||||||||

| Power [kW/hp] |

No.of poles |

Gear stages |

Gear ratio |

Nominal belt speed [m/s] |

Full load torque [Nm] |

Full load belt pull [N] |

Full load current [A] |

Min. face width (L) [mm] |

Min.L Weight [kg] |

| 0.37/0.50 | 8 | 3 | 77.33 | 0.11 | 375.62 | 3478 | 1.64 | 510 | 56 |

| 63.18 | 0.13 | 288.94 | 2675 | ||||||

| 48.58 | 0.17 | 234.77 | 1274 | ||||||

| 41.26 | 0.2 | 187.81 | 1739 | ||||||

| 31.73 | 0.26 | 150.25 | 1391 | ||||||

| 2 | 24.61 | 0.34 | 119.88 | 1110 | |||||

| 20.11 | 0.42 | 95.9 | 888 | ||||||

| 15.46 | 0.54 | 76.72 | 710 | ||||||

| 0.55/0.75 | 8 | 3 | 77.33 | 0.1 | 558.36 | 5170 | 1.67 | 510 | 58 |

| 63.18 | 0.13 | 429.51 | 3977 | ||||||

| 48.58 | 0.16 | 348.98 | 3231 | ||||||

| 41.26 | 0.19 | 279.18 | 2585 | ||||||

| 31.73 | 0.25 | 223.34 | 2068 | ||||||

| 2 | 24.61 | 0.32 | 178.2 | 1650 | |||||

| 20.11 | 0.4 | 142.56 | 1320 | ||||||

| 15.46 | 0.51 | 114.05 | 1056 | ||||||

| 0.75/1.02 | 8 | 3 | 63.18 | 0.13 | 585.69 | 5423 | 2.38 | 510 | 58 |

| 48.58 | 0.16 | 475.88 | 4406 | ||||||

| 41.26 | 0.19 | 380.7 | 3525 | ||||||

| 31.73 | 0.25 | 304.56 | 2820 | ||||||

| 2 | 24.61 | 0.32 | 243 | 2250 | |||||

| 20.11 | 0.4 | 194.4 | 1800 | ||||||

| 15.46 | 0.51 | 155.52 | 1440 | ||||||

| 1.10/1.50 | 4 | 3 | 77.33 | 0.21 | 558.36 | 5179 | 2.27 | 510 | 58 |

| 63.18 | 0.26 | 446.69 | 4136 | ||||||

| 48.58 | 0.34 | 348.98 | 3231 | ||||||

| 41.26 | 0.4 | 279.18 | 2585 | ||||||

| 31.73 | 0.52 | 228.1 | 2112 | ||||||

| 2 | 24.61 | 0.67 | 181.03 | 1676 | |||||

| 20.11 | 0.82 | 142.56 | 1320 | ||||||

| 15.46 | 1.1 | 114.05 | 1056 | ||||||

| 6 | 3 | 63.18 | 0.17 | 670.87 | 6212 | 2.86 | 510 | 61 | |

| 48.58 | 0.22 | 558.36 | 5179 | ||||||

| 41.26 | 0.26 | 446.69 | 4136 | ||||||

| 31.73 | 0.34 | 348.98 | 3231 | ||||||

| 2 | 24.61 | 0.44 | 279.18 | 2585 | |||||

| 20.11 | 0.54 | 228.1 | 2112 | ||||||

| 15.46 | 0.7 | 181.03 | 1676 | ||||||

| 1.50/2.04 | 4 | 3 | 63.18 | 0.26 | 609.12 | 5640 | 2.87 | 510 | 61 |

| 48.58 | 0.34 | 475.88 | 4406 | ||||||

| 41.26 | 0.4 | 380.7 | 3525 | ||||||

| 31.73 | 0.52 | 304.56 | 2820 | ||||||

| 2 | 24.61 | 0.66 | 246.86 | 2285 | |||||

| 20.11 | 0.81 | 194.4 | 1800 | ||||||

| 15.46 | 1.1 | 155.52 | 1440 | ||||||

| 2.20/3.00 | 4 | 3 | 48.58 | 0.34 | 698 | 6463 | 4.86 | 510 | 62 |

| 41.26 | 0.4 | 558.36 | 5170 | ||||||

| 31.73 | 0.52 | 446.69 | 4136 | ||||||

| 2 | 24.61 | 0.66 | 362.06 | 3352 | |||||

| 20.11 | 0.81 | 285.12 | 2640 | ||||||

| 15.46 | 1.1 | 228.1 | 2112 | ||||||

| 3.50/4.76 | 4 | 3 | 31.73 | 0.52 | 609.12 | 5640 | 7.69 | 510 | 73 |

| 2 | 24.61 | 0.67 | 475.88 | 4406 | |||||

| 20.11 | 0.81 | 380.7 | 3525 | ||||||

| 15.46 | 1.1 | 304.56 | 2820 | ||||||

| 4.00/5.44 | 2 | 3 | 41.26 | 0.8 | 507.6 | 4700 | 8.63 | 510 | 73 |

| 31.73 | 1 | 406.08 | 3760 | ||||||

| 2 | 24.61 | 1.32 | 329.14 | 3048 | |||||

| 20.11 | 1.6 | 259.2 | 2400 | ||||||

| 15.46 | 2.1 | 207.36 | 1920 | ||||||

| At the min. face width (L), the total weight of a drum motor grows approx.5kg per 100 mm. | |||||||||

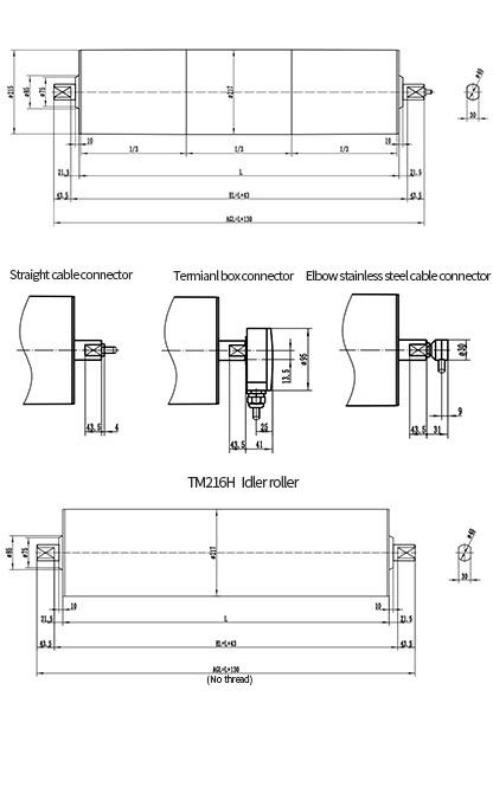

TM216H optional list-drum motor/idler pulley |

||

| Specifications | Drum motor | Idler pulley |

| Shell | ||

| Mild steel crowned | 1 | 1 |

| Mild steel cylindrical | 2 | 2 |

| Stainless steel(std. 304) crowned | 2 | 2 |

| Stainless steel(std. 304) cylindrical | 2 | 2 |

| End housing (front & rear) | ||

| Cast iron | 1 | 1 |

| Cast stainless steel | 2 | 2 |

| Shaft (front & rear) | ||

| Mild steel | 1 | 1 |

| Stainless steel(std. 304) | 2 | 2 |

| Gear box & rear flange | ||

| Cast iron | 1 | 1 |

| Rubber lagging | ||

| Hot vulcanized black smooth rubber lagging | 2 | 2 |

| White and blue rubber lagging in food quality | 2 | 2 |

| Urethane lagging | 2 | 2 |

| Sprockets for modular belting | 2 | 2 |

| V-grooves in the rubber lagging | 3 | 3 |

| Electrical motors | ||

| 3-phase asynchronous motor | 1 | |

| 3*400V/50Hz | 1 | |

| Dual voltage motor | 2 | |

| Most common global voltages at 50 or 60 Hz | 1 | |

| Thermal protection | 1 | |

| Lubricating oil | ||

| No.150 gear oil | 1 | |

| Low temperature oil | 2 | |

| Food grade oil & grease (FDA and USDA) | 2 | |

| Electrical connection | ||

| Straight cable connector | 1 | |

| Elbow stainless steel cable connector | 2 | |

| Terminal box connector | 2 | |

| Oil resistant PVC cable | 1 | |

| LS halogen-free cable | 2 | |

| Screened cable (for VFD and brakes) | 3 | |

| Other options | ||

| Mechanical backstop | 2 | |

| Electromagnetic brake | 2 | |

| Modified for vertical or angled mounting | 3 | |

| Operation with VFD | 2 | |

| Note:1-fitted as standard 2-optional extras 3-available as limited option but need to confirm with manufacturer | ||