TM138H asynchronous oil immersed drum motor.It is mainly used for belt conveying equipment with medium load,the effective power of its motor is up to 1. 10kW.The heavy design makes TM138H more suitable for the belt conveying industry with harsh operating conditions.This kind of drum motor is typically used in:

Motor type:Asychronous, AC, 3 phase

Key words:Belt drive, Oil-filled

Tag:Heavy-duty, Strong torque

AMROLL Drum Motor TM138H-3 *400V/50Hz |

|||||||||

| Power [kW/hp] |

No.of poles |

Gear stages |

Gear ratio |

Nominal belt speed [m/s] |

Full load torque [Nm] |

Full load belt pull [N] |

Full load current [A] |

Min. face width (L) [mm] |

Min.L Weight [kg] |

| 0.25/0.34 | 6 | 3 | 58.87 | 0.11 | 149.09 | 2161 | 0.99 | 390 | 24 |

| 53.21 | 0.13 | 135.1 | 1958 | ||||||

| 48.36 | 0.14 | 122.47 | 1775 | ||||||

| 0.37/ 0.50 | 2 | 2 | 16.87 | 1.19 | 21.87 | 317 | 0.92 | 330 | 22 |

| 15.33 | 1.32 | 19.46 | 282 | ||||||

| 4 | 3 | 58.87 | 0.17 | 143.38 | 2078 | 1.05 | 330 | 22 | |

| 53.21 | 0.19 | 129.59 | 1878 | ||||||

| 48.36 | 0.21 | 119.99 | 1739 | ||||||

| 37.23 | 0.28 | 90.67 | 1314 | ||||||

| 29.33 | 0.35 | 71.44 | 1035 | ||||||

| 26.51 | 0.39 | 64.57 | 936 | ||||||

| 24.1 | 0.42 | 60.03 | 870 | ||||||

| 18.55 | 0.55 | 45.18 | 655 | ||||||

| 2 | 16.87 | 0.6 | 41.51 | 602 | |||||

| 15.33 | 0.67 | 38.92 | 564 | ||||||

| 11.8 | 0.87 | 30.64 | 444 | ||||||

| 6 | 3 | 58.87 | 0.11 | 219.92 | 3187 | 1.5 | 390 | 24 | |

| 53.21 | 0.13 | 199.96 | 2898 | ||||||

| 48.36 | 0.14 | 180.65 | 2618 | ||||||

| 0.55/0.75 | 2 | 3 | 58.87 | 0.34 | 107.96 | 1565 | 1.28 | 330 | 22 |

| 53.21 | 0.38 | 99.08 | 1436 | ||||||

| 48.36 | 0.42 | 89.22 | 1293 | ||||||

| 37.23 | 0.54 | 68.27 | 989 | ||||||

| 29.33 | 0.69 | 55.75 | 808 | ||||||

| 26.51 | 0.76 | 49.54 | 718 | ||||||

| 24.1 | 0.84 | 44.57 | 646 | ||||||

| 18.55 | 1.1 | 35.67 | 517 | ||||||

| 2 | 16.87 | 1.2 | 32.45 | 471 | |||||

| 15.33 | 1.3 | 28.91 | 419 | ||||||

| 11.8 | 1.7 | 22.77 | 330 | ||||||

| 4 | 3 | 58.87 | 0.17 | 217.07 | 3146 | 1.57 | 390 | 24 | |

| 53.21 | 0.19 | 198.17 | 2872 | ||||||

| 48.36 | 0.21 | 178.37 | 2585 | ||||||

| 37.23 | 0.27 | 137.26 | 1989 | ||||||

| 29.33 | 0.34 | 108.16 | 1567 | ||||||

| 26.51 | 0.38 | 99.08 | 1436 | ||||||

| 24.1 | 0.42 | 89.22 | 1293 | ||||||

| 18.55 | 0.54 | 68.39 | 991 | ||||||

| 2 | 16.87 | 0.6 | 62.84 | 911 | |||||

| 15.33 | 0.65 | 57.82 | 838 | ||||||

| 11.8 | 0.85 | 45.54 | 660 | ||||||

| 0.75/1.02 | 2 | 3 | 58.87 | 0.34 | 149.09 | 2161 | 1.63 | 390 | 24 |

| 53.21 | 0.38 | 135.1 | 1958 | ||||||

| 48.36 | 0.41 | 121.65 | 1763 | ||||||

| 37.23 | 0.54 | 94.28 | 1366 | ||||||

| 29.33 | 0.68 | 76.04 | 1102 | ||||||

| 26.51 | 0.75 | 67.55 | 979 | ||||||

| 24.1 | 0.83 | 60.79 | 881 | ||||||

| 18.55 | 1.08 | 48.65 | 705 | ||||||

| 2 | 16.87 | 1.18 | 44.37 | 643 | |||||

| 15.33 | 1.3 | 39.4 | 571 | ||||||

| 11.8 | 1.68 | 31.05 | 450 | ||||||

| 4 | 3 | 48.36 | 0.21 | 243.23 | 3525 | 2.11 | 390 | 24 | |

| 37.23 | 0.27 | 188.56 | 2733 | ||||||

| 29.33 | 0.34 | 148.57 | 2153 | ||||||

| 26.51 | 0.38 | 135.1 | 1958 | ||||||

| 24.1 | 0.42 | 121.65 | 1763 | ||||||

| 18.55 | 0.54 | 93.95 | 1362 | ||||||

| 2 | 16.87 | 0.6 | 86.32 | 1251 | |||||

| 15.33 | 0.66 | 78.87 | 1143 | ||||||

| 11.8 | 0.85 | 62.1 | 900 | ||||||

| 1.10/1.50 | 2 | 3 | 48.36 | 0.41 | 178.37 | 2585 | 2.62 | 390 | 24 |

| 37.23 | 0.54 | 137.63 | 1995 | ||||||

| 29.33 | 0.68 | 108.44 | 1572 | ||||||

| 26.51 | 0.75 | 99.08 | 1436 | ||||||

| 24.1 | 0.83 | 89.22 | 1293 | ||||||

| 18.55 | 1.08 | 68.57 | 994 | ||||||

| 2 | 16.87 | 1.18 | 63.69 | 923 | |||||

| 15.33 | 1.3 | 57.82 | 838 | ||||||

| 11.8 | 1.69 | 45.54 | 660 | ||||||

| At the min. face width (L), the total weight of a drum motor grows approx.3.25kg per 100 mm. | |||||||||

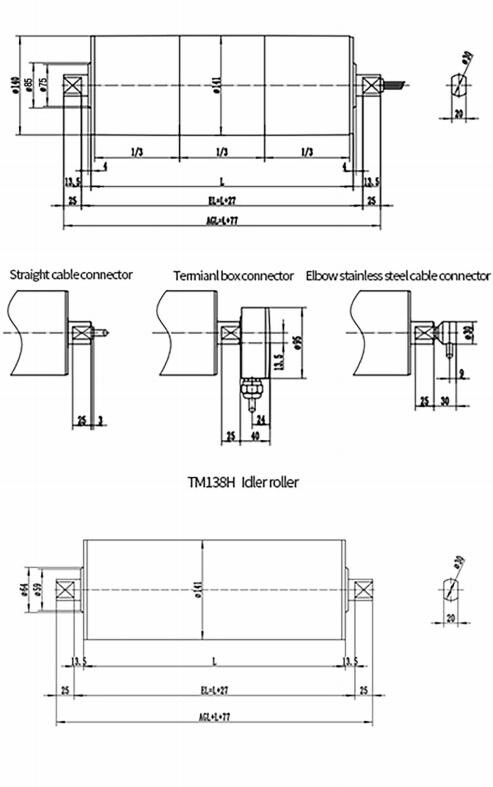

TM138H optional list-drum motor/idler pulley |

||

| Specifications | Drum motor | Idler pulley |

| Shell | ||

| Mild steel crowned | 1 | 1 |

| Mild steel cylindrical | 2 | 2 |

| Stainless steel(std. 304) crowned | 2 | 2 |

| Stainless steel(std. 304) cylindrical | 2 | 2 |

| End housing (front & rear) | ||

| Cast iron | 1 | 1 |

| Cast stainless steel | 2 | 2 |

| Shaft (front & rear) | ||

| Mild steel | 1 | 1 |

| Stainless steel(std. 304) | 2 | 2 |

| Gear box & rear flange | ||

| Cast iron | 1 | 1 |

| Rubber lagging | ||

| Hot vulcanized black smooth rubber lagging | 2 | 2 |

| White and blue rubber lagging in food quality | 2 | 2 |

| Urethane lagging | 2 | 2 |

| Sprockets for modular belting | 2 | 2 |

| V-grooves in the rubber lagging | 3 | 3 |

| Electrical motors | ||

| 3-phase asynchronous motor | 1 | |

| 3*400V/50Hz | 1 | |

| Dual voltage motor | 2 | |

| Most common global voltages at 50 or 60 Hz | 1 | |

| Thermal protection | 1 | |

| Lubricating oil | ||

| No.150 gear oil | 1 | |

| Low temperature oil | 2 | |

| Food grade oil & grease (FDA and USDA) | 2 | |

| Electrical connection | ||

| Straight cable connector | 1 | |

| Elbow stainless steel cable connector | 2 | |

| Terminal box connector | 2 | |

| Oil resistant PVC cable | 1 | |

| LS halogen-free cable | 2 | |

| Screened cable (for VFD and brakes) | 3 | |

| Other options | ||

| Mechanical backstop | 2 | |

| Electromagnetic brake | 2 | |

| Modified for vertical or angled mounting | 3 | |

| Operation with VFD | 2 | |

| Note:1-fitted as standard 2-optional extras 3-available as limited option but need to confirm with manufacturer | ||